Release time:2025-06-11Clicks:

In industries where precision, efficiency, and durability are paramount, high-performance ball valves have become a critical component in controlling the flow of fluids and gases. These valves are designed to withstand extreme conditions and provide reliable performance in various applications, including oil and gas, chemical processing, water treatment, and more. Lishui BSV Valves Supplier, a leading manufacturer in the ball valve industry, takes pride in delivering top-notch solutions tailored to meet the demands of industrial clients worldwide. In this article, we will explore the key features of a high-performance ball valve, focusing on the expertise and innovation of BSV.

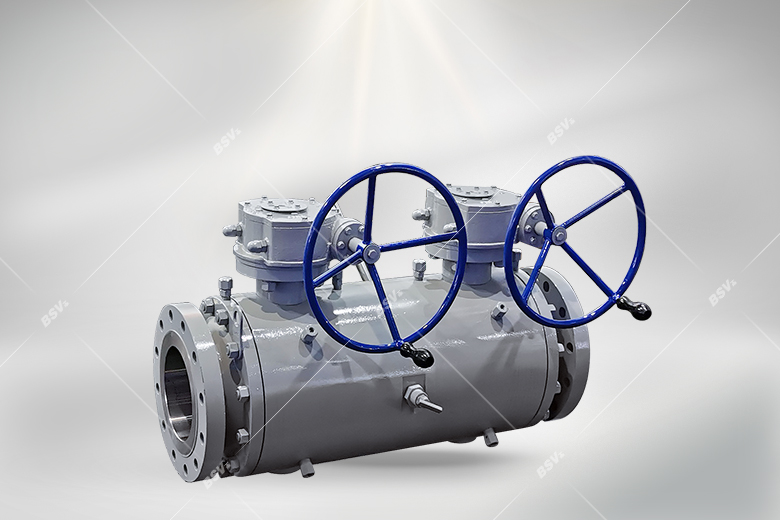

A high-performance ball valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of a medium through it. Unlike standard ball valves, high-performance variants are engineered to handle higher pressures, extreme temperatures, and corrosive environments. They are widely used in applications where precision and reliability are critical, ensuring minimal downtime and optimal operational efficiency.

Lishui BSV Valves Supplier has earned a reputation for manufacturing high-quality ball valves that meet international standards. With decades of experience in the industry, BSV has consistently delivered innovative solutions to address the challenges faced by industrial clients. Their commitment to quality, coupled with advanced manufacturing technologies, ensures that every valve produced meets the highest performance and durability standards.

High-performance ball valves from Lishui BSV Valves Supplier are designed with several key features that set them apart from standard valves. Below, we delve into these features in detail:

One of the defining characteristics of BSV’s high-performance ball valves is the use of premium-quality materials. These materials are carefully selected to ensure resistance to corrosion, wear, and extreme temperatures. Common materials used include:

This meticulous material selection ensures that BSV ball valves can operate reliably even in the harshest conditions.

BSV employs state-of-the-art manufacturing techniques to produce ball valves with exceptional precision. The ball and seat are machined to tight tolerances, ensuring a perfect seal and smooth operation. This precision minimizes leakage and reduces wear, extending the valve’s lifespan and improving overall performance.

BSV’s high-performance ball valves are designed to handle extreme pressures and temperatures. They are capable of operating in conditions ranging from cryogenic temperatures to high-heat environments, making them suitable for a wide range of industrial applications. These valves are rigorously tested to ensure they meet or exceed industry standards for pressure and temperature resistance.

The sealing mechanism of a ball valve is crucial for its performance. BSV incorporates advanced sealing technologies, such as:

These sealing mechanisms ensure minimal leakage and optimal flow control, even in challenging conditions.

Safety is a top priority in industrial applications, and BSV’s high-performance ball valves are designed with fire-safe features. These valves are constructed to maintain their integrity and prevent leakage in the event of a fire, ensuring the safety of personnel and equipment.

Static electricity can pose a significant risk in certain applications, particularly those involving flammable gases or liquids. BSV ball valves are equipped with anti-static devices that prevent the buildup of static charge, enhancing safety and reliability.

BSV’s high-performance ball valves are designed for smooth and easy operation, requiring minimal torque to open or close. This feature reduces wear on the valve components and ensures consistent performance over time. Additionally, low torque operation makes these valves compatible with automated systems, such as electric or pneumatic actuators.

BSV understands that every industrial application has unique requirements. That’s why they offer a wide range of ball valve designs, including:

Furthermore, BSV provides customization options to meet specific client needs, ensuring the perfect solution for any application.

The combination of high-quality materials, precision engineering, and advanced sealing technologies results in valves that offer a long service life. BSV ball valves are built to withstand years of operation with minimal maintenance, reducing overall costs and downtime for clients.

All BSV high-performance ball valves are manufactured in compliance with international standards, such as API, ANSI, ISO, and ASME. This ensures that clients receive products that meet the highest quality and safety benchmarks.

BSV’s high-performance ball valves are suitable for a wide range of applications, including:

When it comes to industrial valves, reliability and performance are non-negotiable. Lishui BSV Valves Supplier stands out as a trusted partner for businesses seeking high-performance ball valves that deliver exceptional value. By choosing BSV, clients benefit from:

High-performance ball valves are an integral part of modern industrial operations, offering precise flow control, durability, and reliability. Lishui BSV Valves Supplier has established itself as a leader in this field, providing innovative solutions that meet the diverse needs of clients across various industries. With a focus on quality, safety, and customer satisfaction, BSV continues to set the benchmark for excellence in the ball valve industry.

If you’re looking for high-performance ball valves that you can trust, look no further than Lishui BSV Valves Supplier. Contact their team today to learn more about their products and services and discover how they can help optimize your operations.

Tags:Cast Iron Valve supplier,Check Valve,Ball Valve